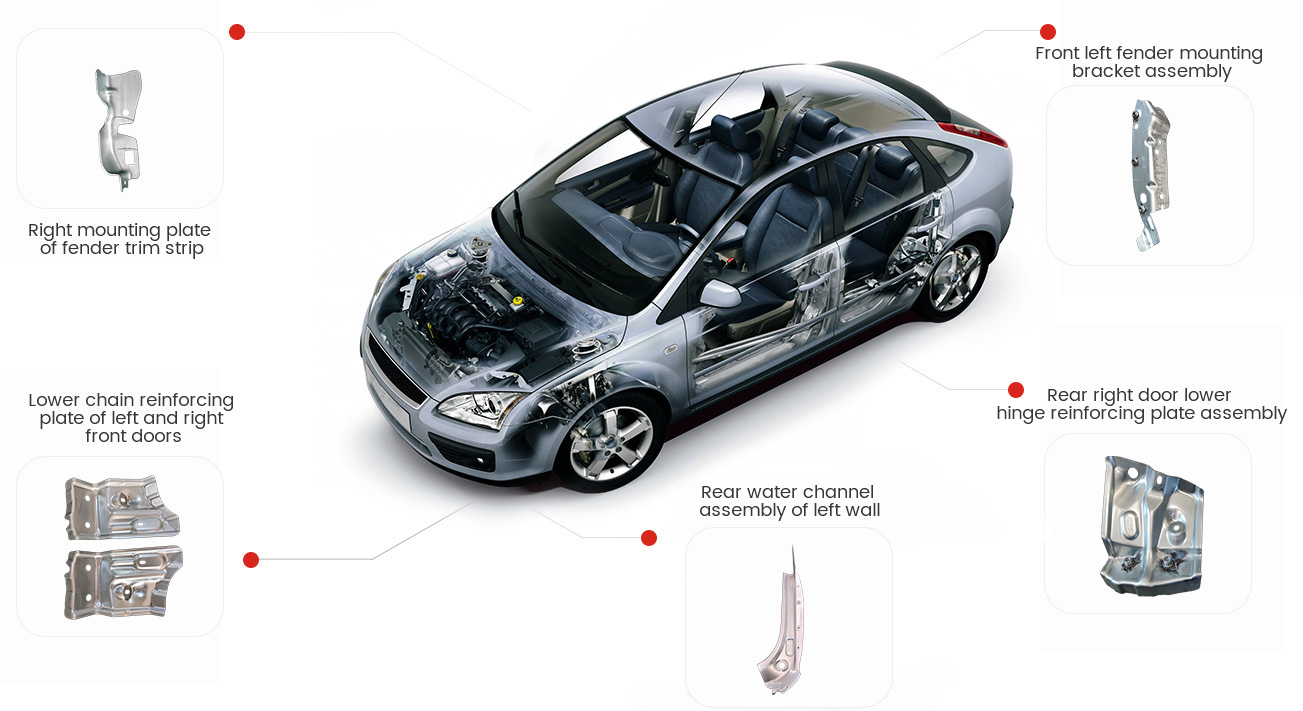

Zhejiang Renda Hardware Products Co.,ltd. founded in July 2003, is located in the Auto Parts Industrial Park of Ningbo Economic and Technological Development Zone. Through more than ten years of development, the company has two factories, one of which covers an area of 6000 square meters. It mainly focuses on the processing and manufacturing of auto parts stamping parts. The second plant area covers an area of about 20000 square meters, mainly engaged in auto parts large stamping, cold forging, hot forging, welding and manufacturing products. 2、 In order to improve product quality and economic benefits, expand product popularity, the company has continuously introduced advanced production equipment at home and abroad in recent years, hired dozens of professional technicians and managers, and improved the management system. The products are characterized by fine workmanship, high technology content, beauty and durability, and enjoy a high reputation in the industry. The products are exported to Japan, Europe, America and other countries, with an annual sales volume of about 100 million yuan in the domestic and international markets. With the strong promotion of the company's "521 strategic objectives", it is expected that the annual sales volume of the company will exceed 300 million yuan by 2022. 3、 Since the beginning of 2015, the company has made a major strategic transformation, adjusted the structure of the company's product line, and constantly carried out the development and production of automotive parts. In May this year, the company invested in the construction of a continuous automatic stamping line led by a 2000 ton oil press. At present, to form a mass production capacity, it is planned to build another continuous automatic stamping line led by a 1600 ton oil press in May June 2018. At the same time, the company has carried out technical upgrading and transformation on more than 50 existing stamping equipment to replace manual operation with robots, and can produce corresponding stamping inner panels of large, small and medium-sized automobiles. At present, the company's main customers are Geely, Honda, Toyota, Gree, etc. 4、 The company passed ISO9001 quality management system certification in 2004, and passed ISO/TS16949 and ISO14001 quality environment system in March 2009. The company always adheres to the business principle of "quality, reputation", and the business philosophy of "honest service, people-oriented". All employees always keep in mind the enterprise tenet of "running a enterprise, creating a brand, and building a image", and continue to provide high-quality products and services for new and old customers. Let us Renda people work together with you to create brilliance.